Sewer & Drain

NuFlow offers a variety of solutions tailored to specific sewer and drain requirements, from small diameter vertical and horizontal connection liners to UV curing, from continuous inversion to pressurized CIPP. NuFlow has the technology, expertise, and support you need to tackle the toughest sewer and drain pipe lining jobs.

and VHCL CIPP Pipe Lining Solutions

NuFlow’s leading structural lining technology, a prime example of Cured In Place Pipe Lining (CIPP), along with Precision PIP (push or pull-in-place) technology, enhances the structural strength of the host pipe and acts as a stand-alone 'pipe within a pipe.' This approach is typically used in drain systems including sewer, storm water, and roof drains, showcasing the versatility of Cured In Place Pipe Lining (CIPP). NuDrain, a key product in our Cured In Place Pipe Lining (CIPP) portfolio, can be installed in pipelines with diameters from 1 ½ inches to over 12 inches.

NuFlow’s Vertical and Horizontal Connection Liners (VHCL) are integral to our Cured In Place Pipe Lining (CIPP) solutions. They enable perfect placement of the liners throughout the entire pipe infrastructure, including wyes and tees, eliminating the need to 'skip the fitting.' This feature underscores the precision and adaptability of Cured In Place Pipe Lining (CIPP) in various pipe repair scenarios.

NuFlow’s Cured In Place Pipe Lining (CIPP) technologies, including NuDrain and VHCL, provide a comprehensive solution for reinforcing and repairing pipes, ensuring long-lasting and reliable pipe infrastructure.

- Pipe diameter applications range from 1 1/2” to 12” with larger custom sizes available

- Used in host pipes consisting of clay, concrete, metal, iron, steel, plastic and fiberglass

- Improves water flow

- Can be installed in junctions, bends, horizontal and/or vertical pipes in one complete application

- Can be installed in pipe with multiple bends, elbows, branches, and changes in pipe diameter

- Can start and stop at any point within the pipe to give greater flexibility with sectional lining

- Residential, Commercial and Industrial applications

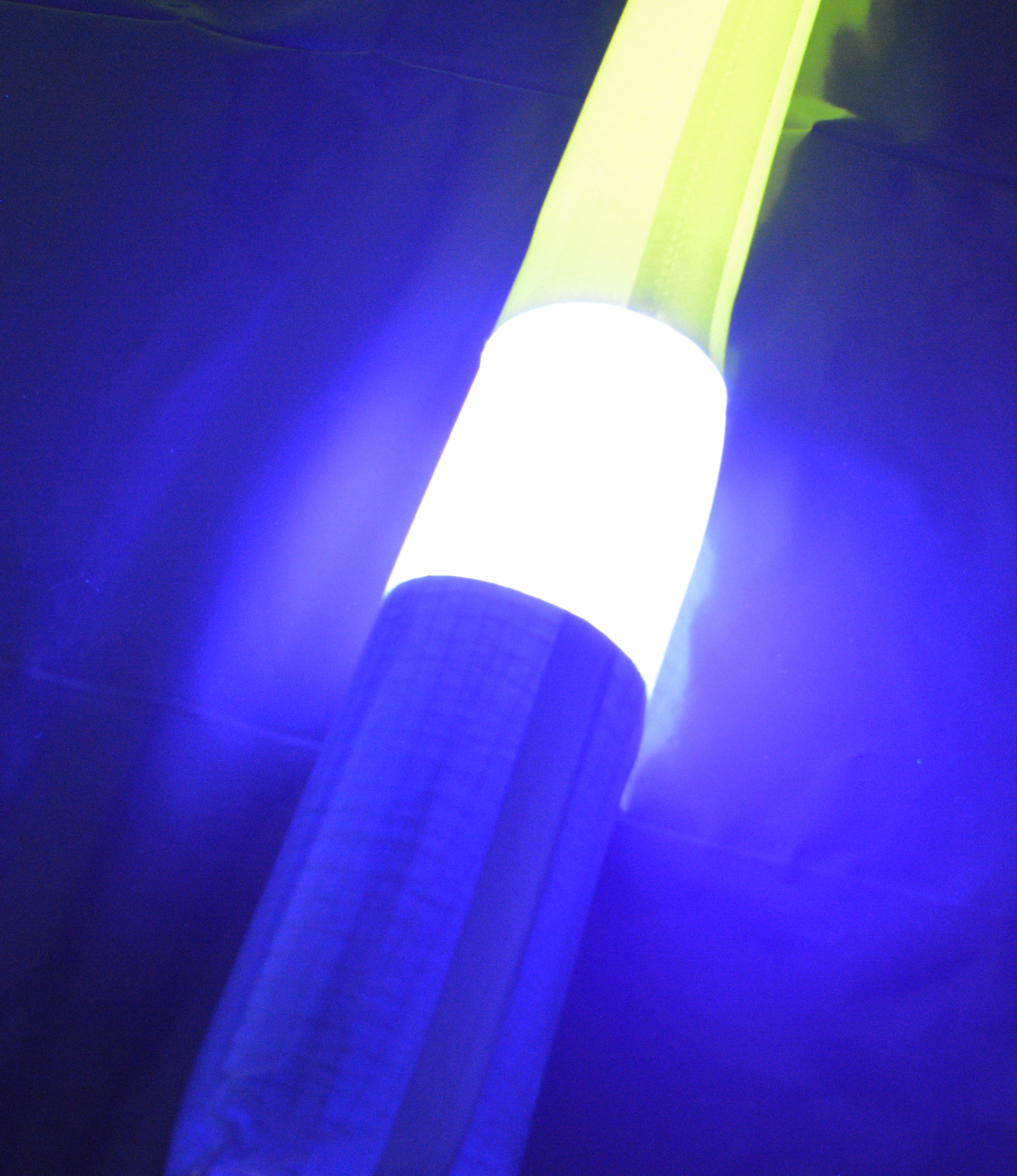

UV Curing Pipe Lining Solutions

UV and Precision PIP (push or pull-in-place) technology minimizes the risk of error by activating liners in place and allowing the contractor to wet out on or off-site. Because the resin is activated in-place with UV light exposure, UV cured resins provide indefinite “pot life” (working time). UV liners cure much faster than the alternative curing methods. Whereas an ambient cure requires 4 to 10 hours of processing time and thermal curing requires 2 hours, UV curing can be completed in as little as 10 minutes.

NuFlow’s NuCure CCUV is industry-leading UV technology at a game changing price.

Repair large diameter pipes with the speed and efficiency of UV curing. UV point repair for pipes 8” to 24” diameter.

Repair pipes as small as 2” in diameter with multiple bends with the speed and efficiency of UV curing.

Introducing NuFlow’s NuTube Inversion equipment. Taking pipe rehabilitation to new lengths.

At NuFlow we pride ourselves on supplying our network of Certified Contractors with the highest quality materials, technology, and know-how to repair even the worst pipe systems failures imaginable. We are pleased to announce that we have teamed up with KrasoTech to introduce NuTube Inversion. These tools provide the options that our contractors need to tackle all of their pipe lining needs.

KrasoTech® GmbH is a family run business and one of the leading companies in the development and manufacturing of equipment for trenchless pipe renovation. For over 20 years, they have been providing innovative and reliable pipe renovation equipment to their partners across the globe.

NuTube Sluice includes a patented two-chamber system for endless inversion without pressure loss to protect the liner from unwanted stretching, bruises, wrinkles, and folds.

Capable of inverting diameter of 9” and below, the NuTube Drum Hybrid changes from drum to a continuous sluice system in a few easy steps.

A simple but smart inversion drum for liners 8” and below

Pressurized CIPP Force Main Pipe Lining Solutions

NuForce structurally repairs high pressure sewer and potable water mains in diameters from 2” to 24” NPS (50mm to 600mm) with minimal disruption. NuForce meets the requirements of NSF/ANSI 61.

Key Features & Benefits

- Composite liner structurally repairs high pressure pipe 2” and up

- Higher crush and burst strength than AC and UPVC

- High stiffness

- 100% solids “zero shrinkage” epoxy resin with advanced fiberglass reinforcement

JOIN

TODAY!

Begin the path to new expertise, product offerings, and revenue streams. NuFlow technicians are highly-qualified educators and can offer the industry expertise, guidance, and resources to help you start installing state-of-the-art NuFlow products in no time.

Let’s get started!

"*" indicates required fields